| |

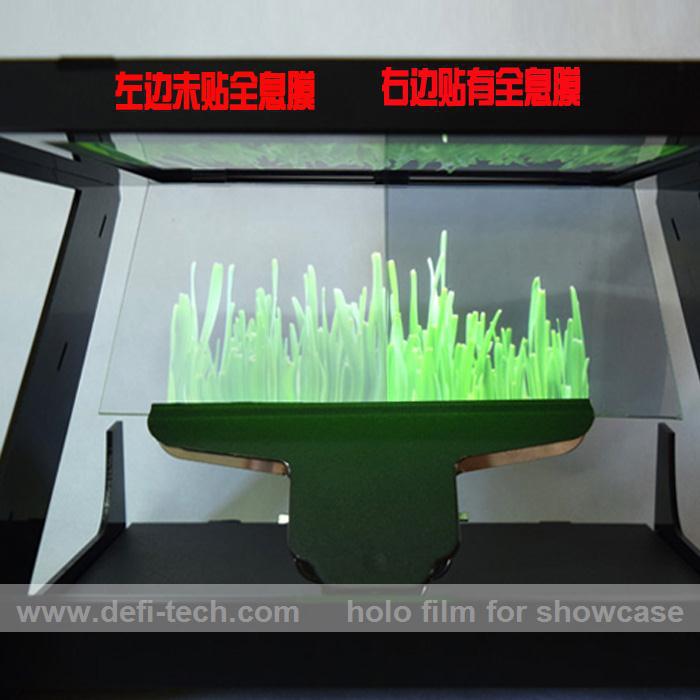

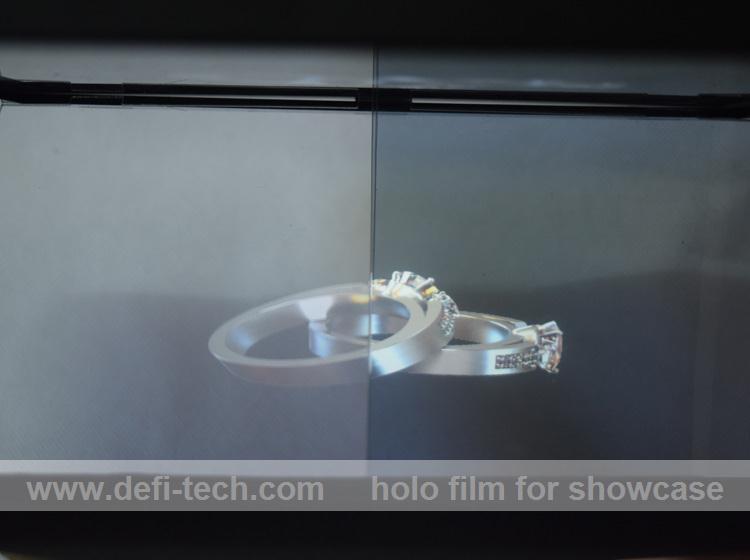

This holo film is suitable for 180 degrees, 270 degrees, 360 degrees showcase.

The holographic reflective film by invasive adhesive layer, hard processing layer, antistatic, easy to stick on the glass and transparent acrylic plate with water.Using a wide range, wide 1524 mm, length of 50 meters. Can be arbitrary cut! A large number of wholesale and retail, welcome to inquiry!

The customer who cannot separate the holographic reflective film , please use sticky tape at the corner of the film ,more than the film, then use nails scraping protective layer.

The holo film, using a complex magnetron sputtering technology made of multilayer dielectric coating process.The most modern production use multicellular dc magnetron sputtering machine worth $24 million.It can make multi-layer nanometer grain that the thickness is smaller than a human hair plating to the world's top (only 1% of the world polyester film production) optical clarity in durable polyester film.

Sticking method:

First step:

Clean the glass, check the glass in the watering can with cleaning solution spray wet glass surface, with a stiff scraping board, water alternating clean glass wiper, when necessary, also can use the shovel scraping shovel sticking dirt, supplemented by special clean cloth around the glass, carefully washed repeatedly, until clean, use tools: watering can, water, rags, shovel, etc.

Note:

1, The surface of glass can't shovel dirt, dust, lint, otherwise the membrane will produce tiny space, between glass and can be inhaled air and cause the breakage of the membrane, which affect the quality of the film projection and projection of the membrane and beautiful.

2, Had better use distilled water, pure water, or filtered tap water and cleaning solution, after precipitation in order to avoid dust.

3, To prepare for antifouling installation site, prevent sewage dirty walls, etc.

Second step:

1, Uncover film positioning and peel off protective film, installed to spray liquid in the exposed surface and clean the glass surface, install the film adhesive stickers on the glass surface, and floating of the projective film carefully.

2, Scrape off water and air bubble,and projection film are obtained, shall be immediately again in projection film surface spraying liquid installation, clean will tear off protective film attached to the stick on the film surface projection, liquid spray installation again, make the surface lubrication, with professional wiper tool to install the film and glass in the middle of the air and liquid out, wiper to light for the first time, and then the continuous cross hard water, glass upper part had better use horizontal wiper, below the top to bottom cross wiper, or around from the middle to the wiper, use tools: soft handle, water shave, watering can, etc.

Note:

1, The activity of aqueous solution, lest appear the quality problem of the bubble, fall off.

2, the lamination process should have a clean workspace, clean with no dirt, ensure the sticker to clean.

3, According to the order in the direction of the cross wiper, residues too much water and air bubble will affect the quality of film.

4, The surface of film can't touch any other place.

Third step:

Edge trimming film, carefully check processing watermarks projection film edges, with scraper drain diaphragm and residual liquid films between the glass and air bubbles, and blank holder to enhance the cohesive force on the edge of the film, cut the film around.Utility: hard film cutting knives, scraper, etc.

Note:

When blank holder to avoid scratch the film surface, non-woven encase hard scraper if necessary.

Fourth step:

Leveling the film surface, and check whether there is a film defects to deal with the remaining bubbles and water damage, as well as the angle of loose parts, can be used with a soft cloth round scraper or hard scraper will bubble out gently, glass and diaphragm stronger bond.Utility: hard scraper, watering can, etc.

Warm prompt:

1, because this product installation method is more complicated needs certain professional skills, before installation, please consult auto 4s shop car tint of the teacher, for installation details do not reach the designated position is easy to have bubble, influence projection effect.

|

|